Matched sealing @ AMBTECH

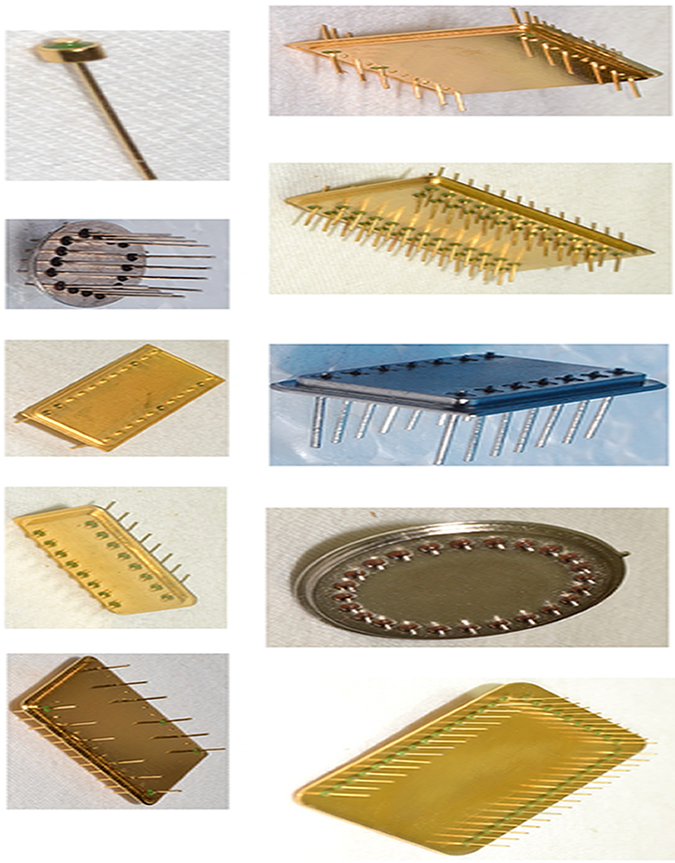

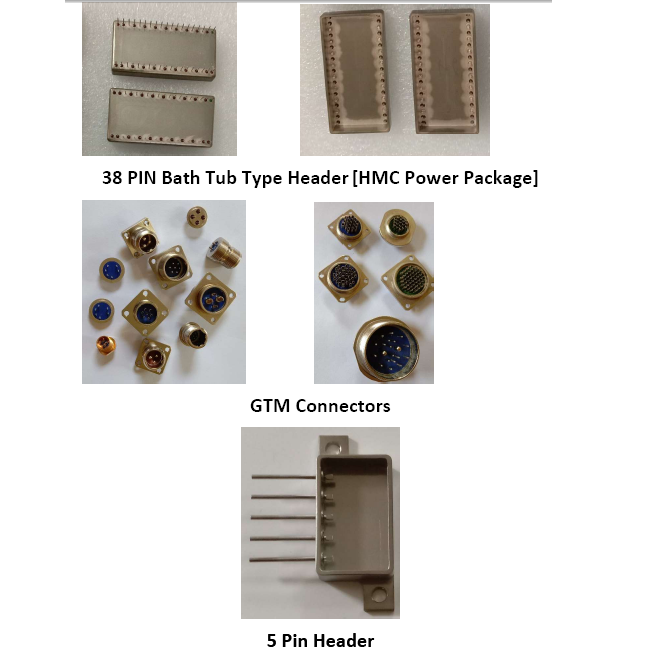

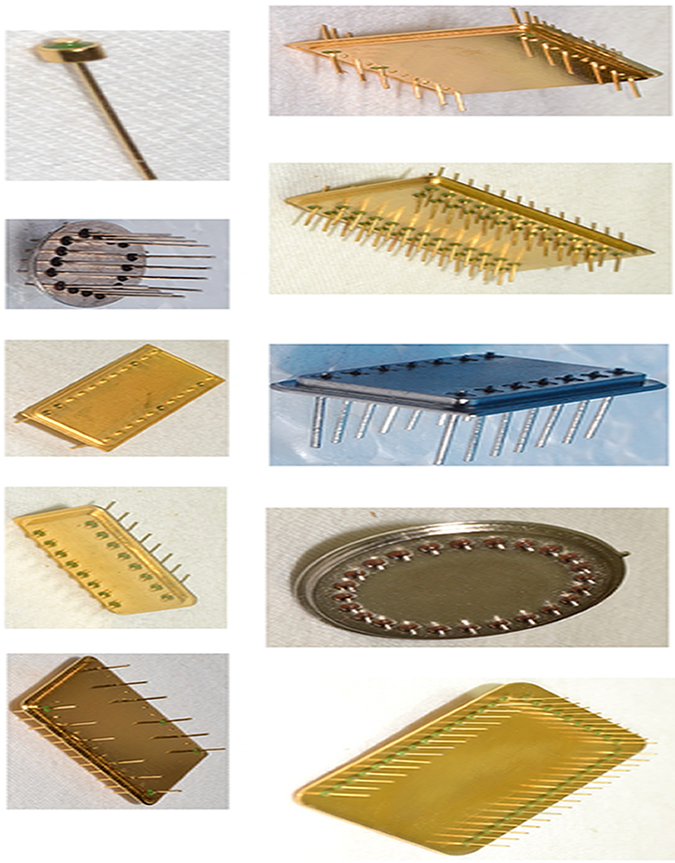

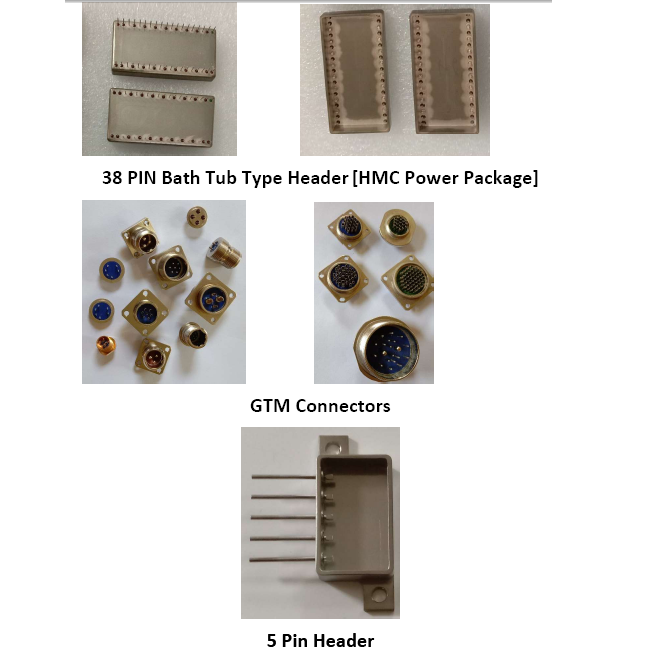

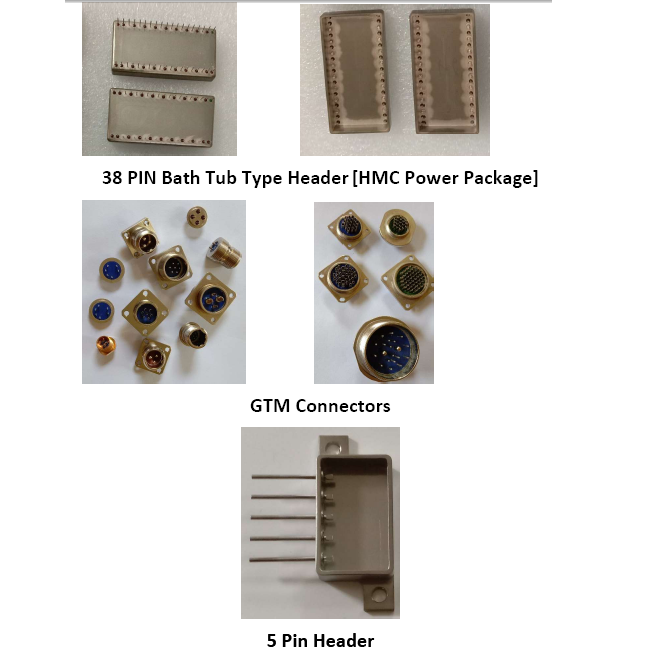

New products

When the CTE (Coefficient of thermal expansion) of the body or housing material matches are very relatively close, usually within 10% of each other. This results in a product in which the stress in the glass is relatively small. See note. This is extremely important in glass hermetic connectors such as the micro-d because of the rectangular shape of the shell. Matched seals can withstand high thermal and mechanical shock and are easier to manufacture compression hermetic seals. The hermetic seal is made by forming a bond through wetting and chemical reactions between the glass and metal. Kovar is the most commonly used material for matched seals.

Body Materials: Kovar, Alloy 42, Tungsten, Molybdneum

Glass Materials: Corning 7056 (Alkali Borosilicate)

Electrodes Material: Kovar, Alloy 42, Tungsten, Molybdneum

Typically Matched Seals maximum allowed temperature is limited by the glass material strain point. Matched seals can withstand high thermal and mechanical shock and are easier to manufacture than compression hermetic seals.